Selecting the best chain for your job

The purpose of this information is to allow you to make informed decisions based on the science behind cutting rocks and concrete. By providing this information, CESSCO Inc. is not endorsing or recommending solutions to your specific job.

The Science of rock and concrete cutting.

- Know your equipment: Diamond cutting tools are designed for the equipment they are meant to support. ICS utilizes different bond formula's and diamond mixtures for each line of chains sold.

- What is being cut: Rocks and concrete consists of various minerals with specific properties. Understanding the Mohs Scale of Hardness allows you to more accurately select the best chain for your job and what to expect when cutting. The more you research this scale the more accurate your chain selection should be, a good place to start is About.com Additional information can be found in their Identification Key for Rock-Forming Minerals.

The easiest way to ensure getting the right chain is If you know the ICS Chainsaw Model you're using

Mouse over & Click on the link to your saw

to see all the genuine ICS diamond chains available for your saw

If you're not sure which saw you have

please call 800-882-4959 and ask for internet sales.

Mouse over & Click on the link to your saw

to see all the genuine ICS diamond chains available for your saw

If you're not sure which saw you have

please call 800-882-4959 and ask for internet sales.

If you're not sure what model saw you own,

please call CESSCO Inc at 800-882-4959 for help.

please call CESSCO Inc at 800-882-4959 for help.

Saws that end

in GC use TwinMAX FORCE3 Chains used on

Gas Saws by General Contractors

Economical Concrete Cutting chains with segments designed for general or specialty use.

|

Saws that end

in F4 use ProFORCE FORCE4 Chains used on

Gas & Hydrualic Saws by Pro Cutters

Concrete Cutting for Heavy Professional Users. These Chains are the most durable chains available

|

Saws that end

in PG use PowerGrit for Ductile Iron Chains used on

Gas & Hydrualic Saws by Pro Cutters

Utility Chain for Ductile Iron Pipe Cutting Safer - Faster - Easier Perfect for Utility Work |

Still not sure which chain type will fit your saw

- Determine "type" of chain

- TwinMAX and FORCE3 Chains

- Are a .3/8" pitch chain with multiple layers of diamonds for cutting concrete and other natural materials.

- Use a guide bar that is grey or silver in color. You may have

to remove the side cover assembly to see the color - the paint won't wear off under the side cover assembly.

The most accurate way to measure any guide bar is to

remove the side cover from your saw and measure tip-tip

(this is mportant to get the overall length of the bar) - TwinMAX chains are designed for Gas Saws

- FORCE4 also called ProFORCE Chains

- Are a .444" pitch chain with multiple layers of diamonds for cutting concrete and other natural materials. These chains are primarily used by Pro-Cutters.

- Use a guide bar that is Black in color. You may have to

remove the side cover assembly to see the color - the

paint won't wear off under the side cover assembly.

The most accurate way to measure any guide bar is to

remove the side cover from your saw and measure tip-tip

(this is mportant to get the overall length of the bar) - ProFORCE chains are designed for Gas Saws, Hydraulic Saws, and Pneumatic Saws

- PowerGrit Chains

- Are a .444" pitch chain with a single layer of large (clearly visable) industrial diamond - primarily used to cut ductile iron.. You'll also notice the diamond segments "wrap around" for side clearance. The diamond segments alternate the wrap from left to right.

- Use a guide bar that is Black in color. You may have to

remove the side cover assembly to see the color - the

paint won't wear off under the side cover assembly.

The most accurate way to measure any guide bar is to

remove the side cover from your saw and measure tip-tip

(this is mportant to get the overall length of the bar) - PowerGrit chains are designed for Gas Saws, Hydraulic Saws,

and Pneumatic Saws.

- TwinMAX and FORCE3 Chains

- If you know what type of chain you're using, you'll need to know the correct size to buy. Pro-Tip - if you know the saw model, buy a CESSCO Combo Pack - These Combo Packs give you added value - buy two chains and get the guide bar for free. Additionally for gas saws - Combo Packs include the correct drive sprocket free. When you click on the link to your saw model all of the Combo Packs shown will ensure you have the correct bar and chain to begin cutting.

- TwinMAX and FORCE3 chains

- Availble in three different bond specs

- Standard or General Purpose are designed for medium grade concrete with light rebar.

- Brick or Abrasive bonds are for cutting soft abrasive materials liek cinder block and brick

- Premium or Plus bonds are for harder and heavier reinforced concrete allowi a more aggressive cut.

- Available in 4 different sizes.

- 25 Segments - These chains provide a 10" cutting depth

- Used on ICS 603GC, 660GC, and RZ60 saws with the 10" guide bar p/n 517869 (overall length 14.8").

- 29 Segments - These chains provide a 12" cutting depth

- Used on ICS 613GC, 680GC, 680ES-GC, Cardi and Edco electric saws with 12" guide bar p/n 71395 (overall length 17.5")

- Used on ICS 623GC, 633GC, 695GC, 695XL-GC saws, also used on Husqvarna/Parner saws - these saws all use 12" guide bar p/n 553207 (overall length 17.4") however it's important to buy the correct combo pack as ICS and Husqvarna saws us differnet drive sprockets.

- 32 Segmets - These chains provide a 14" cutting depth

- Used on ICS 613GC, 680GC, 680ES-GC, Cardi and Edco electric saws with 14" guide bar p/n 513122 (overall length 19.7")

- Used on ICS 623GC, 633GC, 695GC, 695XL-GC saws, also used on Husqvarna/Parner saws - these saws all use 14" guide bar p/n 73600 (overall length 19.9") however it's important to buy the correct combo pack as ICS and Husqvarna saws use differnet drive sprockets.

- Used on Stihl RockBoss saws with ICS guide bar P/N 560807 and ICS Drive Sprocket P/N 562165

- 35 Segments - These chains provide a 16" cutting depth

- Used on ICS 623GC, 633GC, 695GC, 695XL-GC saws, also used on Husqvarna/Parner saws - these saws all use 16" guide bar p/n 71600 (overall length 21.7") however it's important to buy the correct combo pack as ICS and Husqvarna saws us differnet drive sprockets

- 25 Segments - These chains provide a 10" cutting depth

- Availble in three different bond specs

- FORCE4 (also called ProFORCE) chains

- Available in five different bond specs.

- General Purpose are best for medium grade concrete with light rebar.

- ProFORCE Abrasive bonds are for cutting soft abrasive materials liek cinder block and brick

- ProFORCE Premium S bonds faster cutting for use in harder aggregates and heavier reinforced concrete allowi a more aggressive cut.

- ProFORCE Premium L bonds provide a longer life when cutting in harder aggregates and heavier reinforced concrete allowi a more aggressive cut.

- ProFORCE Sandwich Bonds are "L" type on the sides and "S" type in the center - this new formula is designed to provide longer side-clearence life and improved tracking in the cut.

- Available in four different sizes:

- 25 Segment chains

- Provide a 10" cut when used on large hydraulic saws such as the 880F4 and 890F4 - These chains also provide a 10" cutting depth when used on converted 853PRO saws.

- Provide a 12" cut when used on large gas saws such as the 623F4, 633F4, 695F4, and 695XL-F4 saws.

- 29 Segment chains

- Provide a 15" cut when used on large hydraulic saws such as the 880F4 and 890F4 - These chains also provide a 10" cutting depth when used on converted 853PRO saws.

- Provide a 16" cut when used on large gas saws such as the 623F4, 633F4, 695F4, and 695XL-F4 saws.

- 34 Segment chains:

- Provide a 20" cut when used on large hydraulic saws such as the 880F4 and 890F4 - These chains also provide a 10" cutting depth when used on converted 853PRO saws.

- 40 Segment chains:

- Provide a 25" cut when used on large hydraulic saws such as the 880F4 and 890F4 - These chains also provide a 10" cutting depth when used on converted 853PRO saws.

- 25 Segment chains

- PowerGrit chains:

- Come in just the one bond specification designed for cutting ductile iron designed to cut a variety of materials from ductile iron to plastic pipe with far less excavation.

- Available in four different sizes:

- 25 Segment chains

- Provide a 10" cut when used on large hydraulic saws such as the 880F4 and 890F4 - These chains also provide a 10" cutting depth when used on converted 853PRO saws.

- Provide a 12" cut when used on large gas saws such as the 623F4, 633F4, 695F4, and 695XL-F4 saws.

- 29 Segment chains

- Provide a 15" cut when used on large hydraulic saws such as the 880F4 and 890F4 - These chains also provide a 15" cutting depth when used on converted 853PRO saws.

- Provide a 16" cut when used on large gas saws such as the 623F4, 633F4, 695F4, and 695XL-F4 saws.

- 34 Segment chains:

- Provide a 20" cut when used on large hydraulic saws such as the 880F4 and 890F4 - These chains also provide a 20" cutting depth when used on converted 853PRO saws.

- 40 Segment chains:

- Provide a 25" cut when used on large hydraulic saws such as the 880F4 and 890F4 - These chains also provide a 25" cutting depth when used on converted 853PRO saws.

- 25 Segment chains

- Come in just the one bond specification designed for cutting ductile iron designed to cut a variety of materials from ductile iron to plastic pipe with far less excavation.

- TwinMAX and FORCE3 chains

Chain Life - Tips and reasonable expectations

ICS has published these factors that affect chain life:

The primary factor that you can influence is operator experience. The best thing you can do to gain experience is research. To the right is the ICS Cutting Tip Sheet. Awareness of these factors and following the ICS recommended tips will help keep your overall costs down. |

|

|

|

Cutting Distance Expectations

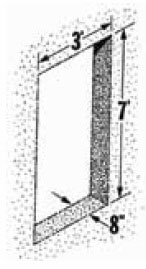

Cutting distance is measured in Inch Feet. To calculate the inch feet of a given job first measure the distance to be cut in feet and then multiply by the depth of cut in inches: Depth of cut in inches multiplied by length of cut.

8 Inch depth multiplied by 20 foot distance = 160 in-ft. |

|

This information is for comparative purposes only. Not to be used to bid jobs.

Get the most out of your

Get the most out of your